Beer Sensory Skills 101 | Malt | Oxidation

This article is part of a series of lessons and exercises that focus on enhancing your sensory skills to better recognize and address brewing problems. By training your sense of smell, taste, mouthfeel, etc., you will have a better understanding of identifying off-flavors/aromas and their causes, which can greatly assist you when looking for solutions to these problems. This blog series will come in many parts dealing with Yeast, Hops, Malt, Water, Infections/Contaminations, and Miscellaneous issues.

Each lesson includes an exercise in a separate tab to assist you in developing your palate and other senses to better detect these flavors, aromas, etc.

Lesson 3.1- Malt: Oxidation - The Tale of the Stale

The Chemistry:

Note: While hops are the most susceptible ingredient to oxidation, this lesson will be focusing more on oxidation of the malt, especially malt extracts, but it will still touch on hops a bit, too. There will be a more in-depth explanation of oxidized hops in a future lesson.

Oxidation profoundly impacts malt during the beer brewing process, influencing both its sensory characteristics and its functionality in brewing. Malt, derived from malted barley or other grains, serves as the primary source of fermentable sugars and contributes essential flavors, colors, and aromas to the finished beer. However, when malt is exposed to oxygen, it undergoes chemical changes that can significantly alter its properties.

One of the most notable effects of oxidation on malt is the development of staling flavors in the finished beer. Lipids present in malt are particularly susceptible to oxidation, leading to the formation of volatile compounds such as aldehydes and ketones. These compounds contribute to off-flavors commonly described as cardboard-like or stale, detracting from the beer's overall quality and freshness. The degradation of lipids through oxidation can occur during storage of the malt or throughout the brewing process, especially during high-temperature steps like kilning or mashing.

Additionally, oxidation can influence the color of malt and subsequently the beer it produces. While controlled browning reactions contribute desirable color and flavor to beer, excessive oxidation can lead to darkening beyond the intended level. This can affect the appearance of the beer, potentially deviating from the brewer's desired color profile. Furthermore, oxidation can compromise the freshness of malt by degrading its delicate flavors and aromas. Freshly malted grains impart nuanced flavors and aromatics to beer, but oxidation can diminish these qualities, resulting in a less vibrant and characterful final product. This is why older cans of HME/LME tend to be darker than new ones when brewed.

Moreover, oxidation can impact the functionality of malt in brewing processes. Enzymes present in malt play a crucial role during mashing by converting starches into fermentable sugars. However, oxidation can denature these enzymes, reducing their activity and potentially affecting the efficiency of the mashing process. As a result, brewers must take precautions to minimize oxygen exposure during grain storage, handling, and mashing to preserve its quality and ensure optimal brewing performance. Proper storage in a cool, dry, and oxygen-free environment, as well as careful handling and milling techniques, are essential measures to mitigate the detrimental effects of oxidation on malt in beer brewing.

Fortunately, with our Mr. Beer and Coopers DIY malt extracts, you don't have to worry about grain storage, handling, mashing. However, we do sell recipes with grains included and these should be stored properly.

The "Stale":

Oxidation in beer can lead to a spectrum of off-flavors, each detracting from the beer's intended taste profile and overall quality. One of the most prominent flavors associated with oxidation is the development of cardboard or papery notes, akin to the taste of wet cardboard or old paper. This flavor arises from the oxidation of lipids, particularly unsaturated fatty acids, which produce compounds such as aldehydes and ketones. When present in beer, these compounds can significantly alter its sensory characteristics, leading to a dull and stale taste experience.

Furthermore, oxidation may manifest as a stale or faded flavor, lacking the vibrancy and freshness typically associated with well-made beer. This dullness in flavor can be indicative of the overall degradation of the beer's sensory profile due to oxidation. Additionally, in more advanced stages of oxidation, beer may acquire sherry-like or nutty aromas and flavors. These characteristics result from the oxidation of certain compounds, such as ethanol, into volatile aldehydes and esters, further contributing to the beer's altered taste profile.

Moreover, oxidation can lead to off-flavors reminiscent of grass or vegetables, which may result from the breakdown of hop compounds, particularly hop oils, during oxidation. This can obscure or mute the characteristic floral, citrusy, or herbal notes typically associated with hop-forward beer styles. Additionally, in some cases, oxidation may impart a metallic taste to beer, often attributed to the oxidation of certain trace metals present in the beer or from contact with metal surfaces during packaging or storage.

Overall, the flavors associated with oxidation vary depending on factors such as the extent of oxidation, the specific compounds involved, and the beer's base ingredients and style. Recognizing and addressing oxidation promptly is crucial for maintaining the quality and integrity of the beer, ensuring a more enjoyable drinking experience

When Oxygen is a Good Thing:

While oxidation is typically seen as undesirable in beer due to its potential to introduce off-flavors and diminish quality, it can have beneficial effects when controlled and applied intentionally. Certain beer styles, such as strong ales, barleywines, and sour beers, may benefit from controlled oxidation during aging. In these styles, oxidation can contribute to the development of complex flavors and aromas, including sherry-like or nutty notes, which enhance the overall character and depth of the beer. Additionally, oxidation can play a role in the aging process of barrel-aged beers, where it helps to develop subtle oak-derived flavors and contribute to overall complexity.

Furthermore, controlled oxidation can enhance malt complexity by facilitating caramelization and Maillard reactions, particularly in beers with rich malt profiles like barleywines and Belgian dubbels. Some traditional brewing methods, such as open fermentation or aging, intentionally expose the beer to oxygen, resulting in a flavor profile that incorporates controlled oxidation. Moreover, in the production of sour beers, oxidation can facilitate the growth of certain microorganisms, such as Brettanomyces yeast and lactic acid bacteria, contributing to the sour, funky, and complex flavor profile characteristic of these styles. While the benefits of oxidation in beer are context-dependent and require careful monitoring, they highlight the intricate interplay between brewing techniques and flavor development in craft beer production.

Avoiding Oxidation:

Preventing oxidation in a Mr. Beer/Coopers DIY kit follows similar principles to larger-scale brewing, albeit on a smaller and more simplified scale. Here are some steps to minimize oxidation when brewing our kits:

• Sanitation and Cleaniness: Ensure all equipment, including fermenters, bottles, and utensils, are thoroughly cleaned and sanitized before use. Any residues or contaminants could lead to off-flavors and potentially exacerbate oxidation.

• Minimize Exposure to Oxygen: Throughout the brewing process, minimize exposure to oxygen as much as possible. When transferring ingredients or wort, avoid splashing or agitation, as this can introduce oxygen into the mixture. Seal containers tightly to prevent oxygen ingress.

• Fermentation Management: During fermentation, ensure that the fermenter is properly sealed to prevent oxygen from entering. Follow the instructions provided with the Mr. Beer kit regarding fermentation temperature and duration to optimize yeast activity and minimize the risk of oxidation.

• Bottling Carefully: When bottling the beer after fermentation, take care to minimize oxygen exposure. Use sanitized bottles and caps provided with the kit, ensuring they are securely sealed to prevent leaks and oxygen infiltration. Avoid unnecessary splashing or agitation during bottling.

• Storage Conditions: Store the bottled beer and any unused malt extract in a cool, dark place away from direct sunlight and temperature fluctuations. Exposure to light and heat can accelerate oxidation reactions, leading to off-flavors and diminished quality.

• Minimize Air Space in Bottles: Fill bottles as close to the top as possible to minimize the amount of air trapped inside. Less air space means less opportunity for oxidation to occur.

• Brew Sooner Than Later: All of our malt extracts have a Best By date on the bottom of the can. This is not an "expiration" date, but an indication of when the malt will start changing due to oxidation. Once this date has passed, the extract will start becoming darker than normal, resulting in a darker beer than anticipated. At first, this won't affect the flavor - just the color. However, after about 2 years passed the date, the extract will become stale and will exhibit many of the off-flavors mentioned above. Store your extract in a cool, dry place below 70° F. The warmer the extract, the faster oxygen will permeate into the can.

• Monitor and Evaluate: Keep an eye on the beer throughout the brewing and bottling process. If you notice any signs of oxidation, such as off-flavors or changes in color, take corrective action if possible. Learning to detect oxidation early can help prevent it from worsening.

By following these steps and paying attention to detail, you can minimize the risk of oxidation when brewing with a Mr. Beer kit, resulting in fresher and more enjoyable homemade beer.

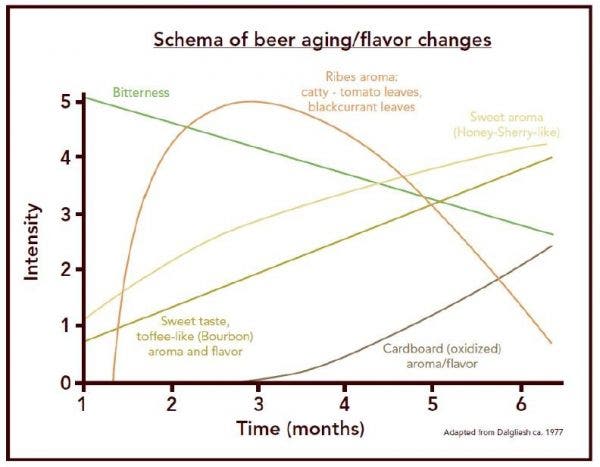

How beer changes over several months of oxygen exposure.

Detecting Oxidation

Aroma:

• Cardboard or Papery: One of the hallmark aromas of oxidation, it's often described as reminiscent of wet cardboard or old paper. This aroma arises from the oxidation of lipids, particularly unsaturated fatty acids, which produce compounds such as aldehydes and ketones.

• Stale or Faded: Oxidized beer may develop a stale or faded aroma, lacking the vibrant and fresh aromatics typically associated with well-made beer. This dullness in aroma can be indicative of overall degradation in the beer's sensory profile due to oxidation.

• Sherry-like or Nutty: In more advanced stages of oxidation, beer may acquire sherry-like or nutty aromas. These aromas result from the oxidation of certain compounds, such as ethanol, into volatile aldehydes and esters, further contributing to the beer's altered aroma profile.

• Grassy or Vegetal: Oxidation can also lead to the formation of off-aromas reminiscent of grass or vegetables. This may occur due to the breakdown of hop compounds, particularly hop oils, during oxidation, resulting in undesirable aromas in the beer.

• Metallic: In some cases, oxidation may impart a metallic aroma to beer, often attributed to the oxidation of certain trace metals present in the beer or from contact with metal surfaces during packaging or storage.

• Loss of Hop Aroma: Oxidation can cause a loss of hop aroma, resulting in a beer that lacks the characteristic floral, citrusy, or herbal notes typically associated with hop-forward beer styles.

Flavor:

• Cardboard or Papery: Oxidation can impart flavors reminiscent of wet cardboard or old paper, resulting from the oxidation of lipids, particularly unsaturated fatty acids, which produce compounds such as aldehydes and ketones.

• Stale or Faded: Oxidation can lead to a taste profile that lacks vibrancy and freshness, presenting as a stale or faded flavor. This dullness in taste suggests an overall degradation in the beer's sensory profile due to oxidation.

• Sherry-like or Nutty: In more advanced stages of oxidation, beer may adopt flavors resembling sherry or nuts. These flavors result from the oxidation of specific compounds, such as ethanol, into volatile aldehydes and esters, further contributing to the beer's altered flavor profile.

• Grassy or Vegetal: Oxidation can induce off-flavors reminiscent of grass or vegetables, stemming from the breakdown of hop compounds, particularly hop oils, during oxidation. This leads to undesirable tastes in the beer.

• Metallic: Some oxidized beers may develop a metallic taste, often attributed to the oxidation of trace metals present in the beer or from contact with metal surfaces during packaging or storage.

• Loss of Hop Flavor: Oxidation can cause a reduction in hop flavor, resulting in a beer lacking the characteristic bitterness, floral, citrusy, or herbal notes typically associated with hop-forward styles.

Overall, the aromas and flavors associated with oxidation can vary depending on factors such as the extent of oxidation, the specific compounds involved, and the beer's base ingredients and style. Recognizing and addressing oxidation promptly is crucial for maintaining the quality and integrity of the beer's aroma, ensuring a more enjoyable drinking experience.

Sensory Training:

• Comparison Tastings: Conduct side-by-side tastings of fresh beer and intentionally oxidized beer to various degrees. Take note of differences in aroma, flavor, color, and mouthfeel between the two samples. This exercise will help you develop a baseline understanding of what oxidation tastes like compared to fresh beer. Comparing brewed Mr. Beer/Coopers DIY extracts of the same style, but varying ages is a great way to explore oxidation at varying stages.

• Blind Tastings: Have someone else pour samples of both fresh and oxidized beer without revealing which is which. Blind tastings remove bias and allow you to focus solely on the sensory characteristics of each sample. Try to identify any off-flavors or other signs of oxidation without knowing which beer is which.

• Dilution Tastings: Dilute a small amount of oxidized beer with fresh beer to reduce the intensity of the off-flavors. Gradually increase the ratio of fresh to oxidized beer until the off-flavors become less noticeable. This exercise can help you recognize subtle signs of oxidation in less pronounced samples.

• Aroma Identification: Practice identifying specific off-aromas associated with oxidation, such as cardboard, wet paper, or sherry-like notes. Use aroma kits or individual aroma compounds to familiarize yourself with these smells outside of the context of beer.

• Regular Tasting Practice: Continuously expose yourself to a wide range of beer styles and pay attention to any deviations from expected flavor profiles. Train your palate by actively tasting and critically evaluating beers, noting any signs of oxidation you encounter.

By consistently practicing these sensory perception exercises, you can train yourself to detect oxidation in beer more accurately and confidently, enhancing your ability to evaluate beer quality and identify potential issues.

Recommended Beers For This Lesson

Oxidation, when controlled and balanced, can contribute positively to certain beer styles, adding complexity and depth to their flavor profiles. Here are some beer styles where oxidation is often considered acceptable or even desirable in a controlled aging process:

It's important to note that while oxidation can enhance the flavor profile of these beer styles when properly managed, excessive oxidation leading to off-flavors or overpowering aromas is generally undesirable. Brewers must carefully monitor and control the aging process to achieve the desired balance of flavors and ensure high-quality beer.